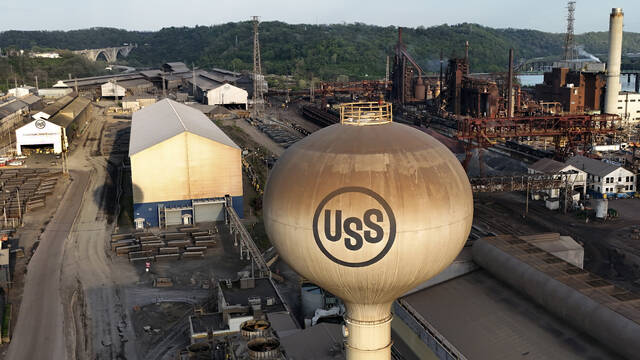

U.S. Steel’s notoriously outdated Edgar Thomson Works handles the molten substance left behind by smelting iron ore the same way it did 150 years ago: by dumping it into slag pits.

They’re as low-tech as they sound.

First, molten iron comes flowing from the blast furnaces. The slag, which rides on top of the iron, is then diverted down a runner into one of two open pits and doused in water to cool.

One pit is used one day, the other the next. In between, the slag is dug out by payloaders, loaded into tri-axle trucks and permanently disposed at a landfill.

“It’s a very primitive process,” said Don Jackson, vice president of United Steelworkers Local 1219, which represents Edgar Thomson Works employees.

The system is about to change as Nippon Steel, the Japanese firm that bought U.S. Steel in June for nearly $15 billion, sinks $100 million into a slag recycler.

The facility will create 15 to 20 full-time positions at the plant, which straddles Braddock and North Braddock.

It marks the first major step in Nippon’s promised $2.4 billion Mon Valley spending spree.

“We can expand revenue by selling the slag, the byproduct, and (there is) also the benefit of reducing waste and air emissions,” said U.S. Steel spokeswoman Amanda Malkowski. “It’s a win-win.”

The slag’s new path will start in a granulation tank, where it’s cooled and formed into small pieces. From there, the material will go to a de-watering unit to dry out before moving into storage.

This type of process allows slag to be used to make cement or build highways.

Unlike the pits, the recycler will be fully enclosed and able to trap harmful pollutants, according to Malkowski. The new material also results in fewer emissions when handled, she said.

Environmental advocates are less than impressed.

“We always approach anything U.S. Steel is saying about emissions reductions with a lot of skepticism,” said Patrick Campbell, executive director of the Group Against Smog and Pollution.

Since 2020, county regulators have fined U.S. Steel about $64 million for pollution violations at its Clairton Coke Works.

The Edgar Thomson Works has been compliant, by comparison, accumulating just a fraction of those penalties.

Hilary Lewis, steel director at Industrious Labs, said “U.S. Steel needs to invest in transformational technology that brings pollution to near-zero, not just waste recycling.”

The company’s air pollution permit application with the Allegheny County Health Department will offer more details about emissions reductions. The application will be filed in the next few days, according to Malkowski.

“We want to get it operating as soon as possible, so we’re hoping for a swift and efficient permit process,” Malkowski said.

Once it starts, construction is expected to take at least a year.

The health department did not immediately return a request for comment.

The company blamed delays in the environmental permitting processing as it cancelled a billion-dollar investment plan for the Mon Valley Works in 2021.

Big spending promises have been met by skepticism by some U.S. Steel workers ever since.

“I won’t get happy about it until I see it built,” Jackson said.

He expects most of the Mon Valley Works investments won’t happen until after workers get a new union contract. The existing deal, which covers about 3,000 employees, expires in September 2026.

U.S. Steel also said it’s investing about $200 million to improve the hot strip mill at the Gary Works in Indiana, enabling it to optimize production costs and expand its offerings.

United Steelworkers International President David McCall expressed support for the investments, adding the “capital investment is a positive indicator of long term security for our members.”

The Irvin Works in West Mifflin is slated for even more extensive work on its hot strip mill. Nippon has promised to sink at least $1 billion into upgrading or replacing it.

Overall, Nippon says it will spend $11 billion on U.S. Steel facilities across the country through 2027.