A new hands-on course with recently acquired machines will soon begin at Quaker Valley High School.

Pre-engineering and technology teacher Mike Santucci is gearing up to launch his manufacturing and fabrication course this month.

It starts his second 12-week program this school year.

Students are finishing up construction and home maintenance as well as modified drafting and design classes.

The new course, open to all high school students, is part of a curriculum expansion that the school board approved in April and made possible through a grant.

“I have a background in linking students with careers in manufacturing,” Santucci said. “Manufacturing is one of the backbones of the Pennsylvania economy. From here, we can see manufacturing companies literally through the window over in the (Leetsdale) Industrial Park.”

Santucci said 36 students have signed up for the course, which will be split into three classes of about 12 students each.

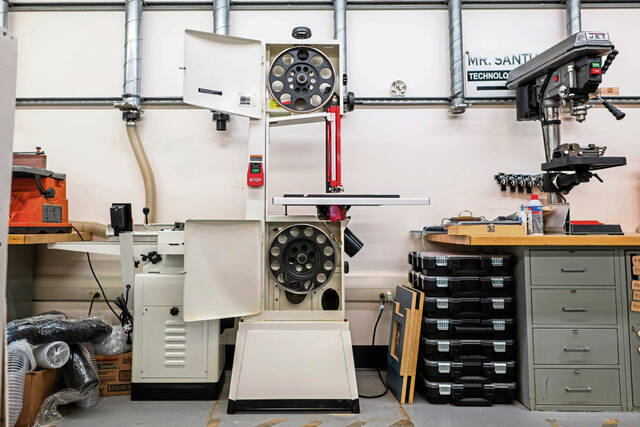

His lab was recently outfitted with an Epilog laser engraver, a Computer Numeric Control milling machine from Forest Scientific Corp., two new industrial Jet band saws, as well as some 3D printers, plastic and metal forming equipment, precision measuring equipment and other tools.

Students can create a design on a computer in an adjacent room and send it to the CNC machine, which will then cut wood and plastics to their specifications. The laser engraver will allow learners to personalize things like cups, coasters and much more.

Santucci said he spent more than a year researching companies to ensure students work with the best quality machines and those used by regional manufacturing companies.

“Trying to teach kids about modern manufacturing, which uses these high-precision, high-tech state-of-the-industry tools, you actually need to have the tools,” Santucci said. “I’m really excited to get it started.”

Program funding

The course and equipment purchases were made possible through a $184,000 state Department of Community and Economic Development’s Manufacturing PA Training to Career grant and a $25,000 commitment from the school district.

The grant also covers Santucci’s salary, benefits and training on the machines to launch the program.

District Business Manager Brooke Baker said Quaker Valley’s contribution was not a grant requirement, but an investment in student education.

“Getting these machines in place at the high school level was on our priority list,” Baker said.

The investment aligns with a statewide push to close workforce gaps, increase career readiness and support students on all post-secondary paths.

State Sen. Devlin Robinson and state Rep. Valerie Gaydos were among the district supporters for the funding.

“As a small business owner and advocate for education and manufacturing, I recognize the importance of equipping students with the technical skills and hands-on experience necessary to thrive in today’s manufacturing and engineering industries,” Gaydos said in a statement. “Quaker Valley High School will help bridge the gap between classroom learning and industry expectations, ultimately contributing to the growth of our state skilled workforce.”

Student perspective

Senior Will Newlin was among the first to use the new tools. He became Santucci’s teaching assistant at the beginning of the year and was previously in Santucci’s robotics classes.

“It kind of gives me the freedom to create things that I want and work with new machines,” Will said. “It’s really cool when you can kind of create something in your head. You have this vision of something you want to make. To be actually able to make it and go through that process is awesome.”

Manufacturing students will not only learn new skills, but have a chance to help out teachers and students in other classes.

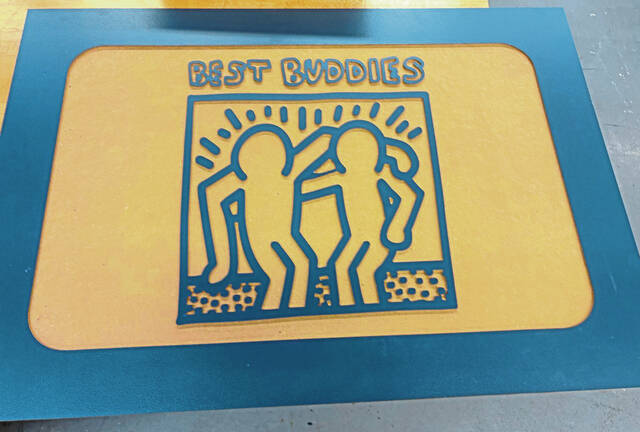

Will created a large wooden “Best Buddies” logo for art teacher Nina Strelec’s glass mosaic class.

It provides a framed workspace for her students to collectively add pieces and create something unique.

“It’s really cool to be able to build something that benefits others,” Will said. “Usually you’re just making something for yourself. To be able to build something for a larger purpose is cool.”

Will said Santucci is a very helpful and knowledgeable teacher who has made an impact on his learning experience.

“I may end up in a design class in college and look into that field,” Will said.

Strelec, who is still collecting glass for the logo, said the idea for a cross-curriculum project originated from an effort to help one of her life skills students who was having a little trouble staying in the lines of his project.

“I’ve tried to adapt a couple things using tape and other ideas,” Strelec explained. “I came to Mike Santucci and said, ‘Hey. What if we cut out some wood at the same thickness of the glass. And then he has a border and a framework to work inside of.’

“Maybe we can make a larger version for all of the life skill class that we can get together and do it collaboratively. Mike jumped on it right away.”

Strelec said the new tools have made creating and customizing things much easier.

“I already come in here on my own and cut the wood to size for my mosaic class,” she said. “(Students) come up with an individual design and I just (use) the miter saw and I cut the wood myself. In minutes, I can customize what they need for a piece of wood and they can start their project. I don’t have to order in advance. Everybody doesn’t have the same size (material). … The potential is so much more.”

Best Buddies is an international organization that creates one-to-one friendships, employment and leadership development for people with intellectual and developmental disabilities.

There are Best Buddies chapters in nearly 1,900 middle schools, high schools and colleges around the world.

“This program helps students in our Life Skills program develop even more friendships and become socially active in high school activities,” Strelec said.

In addition to expanded classroom instruction, the district will collaborate with regional employers in and around the Leetsdale Industrial Park to offer students job shadowing, industry site visits and potential pre-apprenticeship experiences.

The district currently has relationships with the German American Chamber of Commerce, Catalyst Connection, Schroeder Industries and other local manufacturers.