Woodworking isn’t easy.

But 78-year-old Larry Eddy makes it look that way.

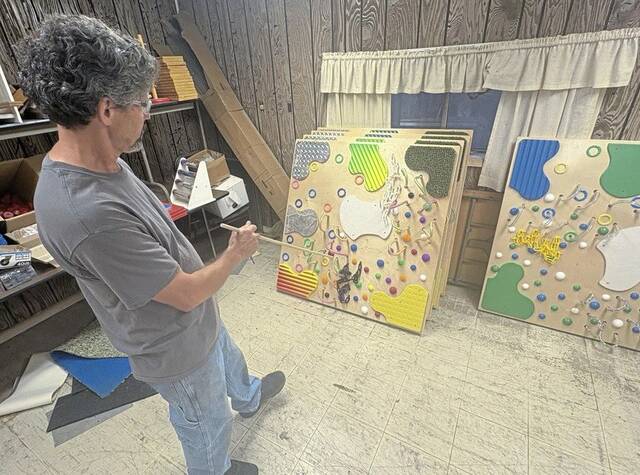

He — and his family — have been turning flat pieces of plywood into 3D art walls at his woodworking shop off Route 908 in Fawn.

The interactive, tactile walls are ordered by West Deer-based TFH Sensory Needs Toys, which specializes in equipment and toys for people with special needs.

“It’s exciting to tell people,” said Dave Eddy, Larry’s nephew. “They ask what my uncle does, and it’s hard to explain. We do make toys, but they’re special toys. Knowing that a toy is going to be used as a tool is pretty impressive.”

The tactile wall panels aim to stimulate people through different fidgets and touch.

A “textured tactile wall,” for example, features 15 textures on the natural wood base; a “loopie wall” also incorporates 15 surfaces on the panel, as well as a tunnel where people can roll balls down through the wall.

Other products include a “tranquil wall” that has 12 shapes and sensations and a “percussion junction” auditory wall that includes boomwackers, a set of drum heads, a tambourine, sleigh bells, a xylophone and pat bells.

Larry Eddy estimated that, in 2023, his shop made more than 500 walls.

“You hope it helps some people out,” he said.

Larry Eddy of Fawn remembers learning how to woodwork in high school and from his family when he was young. He still lives in his family home off Route 908 in front of his warehouse.

Larry Eddy says he started woodworking professionally in 1978 or ’79. He started off making high-end patio furniture, he said, like porch swings.

Now, his work primarily consists of the tactile walls for TFH. He said TFH approached him decades ago to see if he would be interested.

The rest is history.

Larry Eddy said he has been building items for TFH for more than 30 years.

“What he’s been doing for the past 20 to 30 years is remarkable,” Dave Eddy said. “He’s been a one-man show.”

The production warehouse is the perfect place for crafting the walls: it’s large enough to accommodate the demand for the tactile walls, but small enough that things can be custom, Larry Eddy said. He said most people don’t even know the warehouse is there.

“It’s a niche thing,” he said.

Now, the business is beginning to transition to the younger generations of the Eddy family.

About 21⁄2 years ago, the Eddys installed an automated, CNC router to assist in some of the production. The machine can be programmed by a computer on where and how deep to drill on a piece of plywood.

“We modified it and made it what it is now,” Dave Eddy said. “Prior to the machine, everything was hand done by Larry.”

Dave Eddy estimated the machine has saved about 75% of the time it takes to create a wall.

“But there’s still a lot of time that goes into it,” Larry Eddy said.

Those advancements are a contributor as the family business gets passed down to the rest of the family.

There’s a three-year transition plan for the younger generation to take over the business, and still keep Eddy involved, his nephew said.

Dave Eddy has a similar background in woodworking to his uncle, who taught him how to use a band saw when he was 7.

He has been around Eddy Woodworking his entire life; from a business point-of-view, he’s been involved with his uncle for about three years.

“When I was in high school, I wanted to be his apprentice. I didn’t know what I was going into, and he said to go to college,” Dave Eddy said.

“From that time on, he’s continued to do what he’s been doing, but watching as he’s getting older. And since the inception of the CNC machine, that really lit a fire under me and the rest of my family. We said, we can make this happen. It’s a viable transition.”

Larry Eddy looks forward to his younger relatives carrying on the family business.

“The last few years have been the most rewarding part,” he said. “They’ve worked for me; I appreciate them.”

Dave Eddy said it was important for him that the small business remains in the family until he’s at least his uncle’s age.

“When I retire, I want to work here, and work until I can no longer work,” he said.