Technology in 3D printing is advancing and one day could rival traditional manufacturing techniques, according to a local expert in the field.

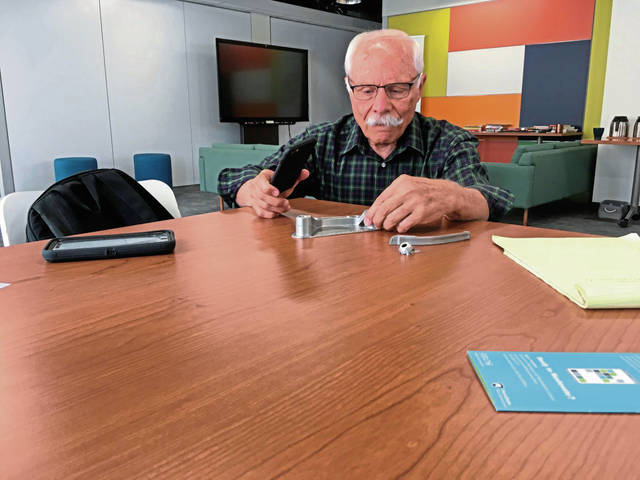

Howard Kuhn, a University of Pittsburgh adjunct professor who has taught additive manufacturing — another term for 3D printing — for the past 15 years, was among those who took in a demonstration of a metal 3D printer Tuesday at The Corner in New Kensington, a co-working and entrepreneurial space affiliated with Penn State New Kensington.

Kuhn, of Summit Township, liked what he saw.

“I haven’t seen this machine up close,” Kuhn said of the demonstration. “It’s all really fun.”

Miller 3D Printing Systems of Harmony demonstrated a machine known as a Markforged Metal X 3D Printer. The company’s Sean Farrell said the machine alone costs $100,000 and the complete system can run up to $150,000.

Farrell said the printer can make a variety of items, including metal parts for older equipment that no longer can be found and custom pieces such as brackets. He displayed a stainless steel handle for a Ducati motorcycle that had been printed over eight to nine hours.

“You can do things (with a 3D printer that) you can’t do through traditional manufacturing,” Farrell said.

Metal 3D printing is viable for making up to about 1,000 parts per year, but not tens of thousands, Farrell said.

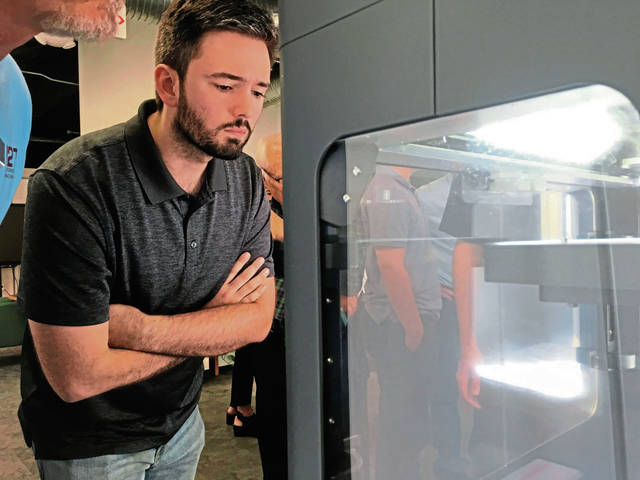

Chris Averona of Shaler, a mechanical engineer, looked on intently as the 3D metal printer, sitting atop a table, began a job. He was one of three people from his company, Integrated Industrial Technologies in Blawnox, who attended the open house.

Averona said his company does plastic 3D printing on-site, and wanted to see what Miller 3D is offering as it considers expanding its capabilities. He said his company could use a metal 3D printer for parts that are awkward or inconvenient for its machine shop to make.

“I think it’s an awesome machine,” he said of the metal 3D printer. “This one seems pretty easy to use. There’s not a big learning curve.”

Kuhn said 3D printing was previously limited to quickly making prototypes and toys. But with the move to additive manufacturing and metal 3D printing, it is advancing to where metal parts such as ones used in cars and airplanes can be printed and the process can be an economical alternative to conventional processes such as casting and forging.

Currently, parts made with metal 3D printing are better than casting, but fall short of forging, Kuhn said. But, he said, “I think they’re not far away from it.”

He said metal 3D printers can make shapes that can’t be made conventionally, and they can make them lighter, a highly desired trait in the aerospace field.

Tuesday’s event was the first equipment open house at The Corner, which opened in December 2017, according to Alyssa Pistininzi, community operations manager for The Corner.