For decades, the Alcoa Technical Center was like a city within a township.

Located in rural Upper Burrell, the sprawling research and development complex first developed in 1964 has its own ZIP code, wastewater treatment plant and fire and emergency medical response.

About 1,200 people worked there at its peak in the late 1990s to early 2000s. They could dine in the center’s full-service cafeteria.

The center has been the birthplace of new aluminum alloys across the aerospace, automotive, commercial transportation, metal joining and industrial market segments. More than 600 active patents and trade secrets originated there.

“This is where the true innovation that supports our company is created,” said Shawn Sullivan, the center’s managing director since March 2019 who started with Alcoa in 2008 as a senior engineer.

The innovations include aluminum beverage cans; aluminum hoods, doors and liftgates for vehicles; a proprietary surface treatment critical to the aluminum Ford F-150 pickup; and high-strength aluminum alloys for wings and fuselages of commercial and defense aircraft and to support the production of modern space launch vehicles enabling resupply and crewed missions to the International Space Station.

The technical center is now the Arconic Technology Center, taking on the name of a successor to the Alcoa legacy. It is Arconic’s sole research and development facility, not replicated anywhere else.

Far fewer people work there under Arconic, between 120 and 125. Four of the seven buildings are vacant and unused. The cafeteria is no longer in operation, and there are large swaths of empty parking lots.

Alcoa maintains a presence on the campus, owning one building. Spokesman Jim Beck would not disclose how many Alcoa employees work there.

The center “provides a location for Alcoa employees to work on various technologies that support our vision to reinvent the aluminum industry for a sustainable future,” he said. “It was at this location, in fact, where Alcoa first developed a carbon-free smelting process that formed the technology basis for our ELYSIS joint venture.”

What was once a single-owner, single-purpose facility could become in essence a new business park, as Arconic is preparing to place its four vacant buildings up for sale.

But while today’s Arconic is a fraction of the size of yesterday’s Alcoa, the innovation at the center continues, and the company’s leaders say they are poised for growth emerging from the covid pandemic.

“We are continuing to develop new proprietary alloys for a range of product applications, including light weighting for battery electric vehicles, structural alloys for next generation space launch vehicles, corrosion-resistant aluminum clad products for advanced heat exchangers/HVAC systems, and higher strength aluminum alloys for improved thermal management in battery cooling systems,” spokeswoman Tracie Gliozzi said.

A recent product is a new high formability alloy that enables enhanced styling designs for vehicles.

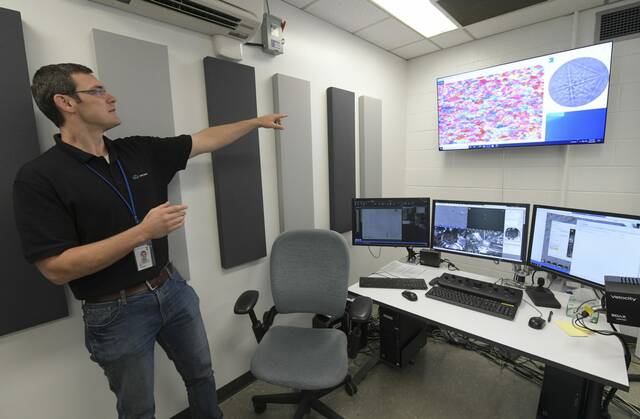

“In addition to developing new alloys for our various markets, the scientists and engineers at ATC are actively developing artificial intelligence tools, ranging from complex innovative computer simulations, machine learning algorithms and advanced manufacturing tools that help to improve our production processes,” she said. “These process technologies are a key part of supporting our current operations, and as we develop new sustainable manufacturing processes we will rely on these automation and advanced control system technologies to minimize energy usage and lower our overall environmental impact.”

While Arconic has consolidated into three buildings, including the original Building A that remains in use, Sullivan said they were chosen in part because they allow room for expansion. The company recently had 13 open positions.

“We’re in a growth phase now,” Sullivan said. “We’re constantly looking for talent.”

At Arconic’s recent Investor Day, CEO Tim Myers said the company is preparing for year-over-year double growth.

“Arconic Technology Center, which is where the company’s innovative product and process solutions begin, has been actively recruiting local talent to help the company pursue these growth targets,” Gliozzi said.

Arconic scaled back the number of employees at the center during the pandemic, to 50% at the lowest point, but they have since all returned, Sullivan said.

“We work flexibly with people,” he said. “One advantage we have out here is space.”