A group of scientists and technology companies from the Pittsburgh area want to torture the covid-19 virus literally to death, and now they have a state grant to help them do so.

That’s a bit of an oversimplification, but a big part of the state’s $68,000 Manufacturing PA grant awarded to the University of Pittsburgh and its partners, ExOne in North Huntingdon and Ansys in Canonsburg, involves the concept of “torturosity.”

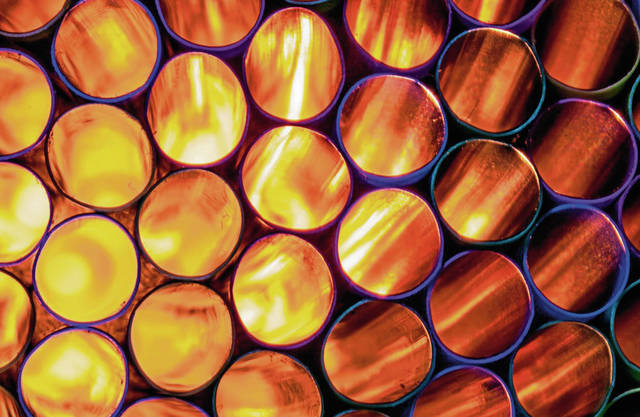

It is the act of forcing air and virus particles through a giant filter maze of miniature pathways, trapping viral particles along the way and using the natural antimicrobial properties of copper to neutralize them.

“Torturosity is also how a river flows and filters out sediment — very windy — and that’s what we’re doing here,” said Markus Chmielus, an associate professor in Pitt’s Engineering and Material Science Department. “Particles will be bouncing against walls all the time and sticking. And when it sticks to copper, it dies.”

The challenge then became creating a copper filter that could be comfortably worn as part of a mask.

Enter ExOne, a company focused on 3D metal printing by way of additive manufacturing. Its process uses metal powder as the base material and can be used to create the sort of intricate-yet-lightweight copper filters Chmielus envisioned.

“A traditional metal part is made from a single chunk of metal,” ExOne CEO John Hartner said. “You machine away maybe 70% of it and you have your part, but the excess metal is thrown away. What we do is start with powder, create 1,000 ‘slices’ of the part we’re making, then build it up layer by layer with powder, and all of the excess is reusable.”

Sustainability and recycling were at top of the priority list for both Chmielus and Hartner.

“The goal is to create personal protective equipment filters that are small enough and light enough that you can breathe through them, while also filtering enough particles to reach N95 (mask) levels,” Chmielus said.

The $2 million Manufacturing PA initiative will provide grants to 29 student research projects that aim to advance innovation in several sectors of manufacturing, from advanced medical, to waste sustainability, to artificial intelligence.

“We have a graduate student working on this project for the next year, along with an undergrad student and senior design teams of mechanical engineers who are really looking at the design of mask filters,” Chmielus said.

That’s where Canonsburg-based company Ansys figures in.

“We’re a technology company,” Hartner said. “We want to be able to allow users to design filters faster and leverage the technology we have.”

Ansys specializes in engineering simulation software, and its engineers are building a data set based on particle simulations for different filter designs and various levels of torturosity.

“The objective is for us to be able to say, ‘For this particular application with a certain flow rate, you want to take out a certain number of particles, and the size and geometry is like this,’” Hartner said. “We’ll produce test patterns, which they’ll run particle tests on. They’ll put that data back into the model, and it’ll be able to better learn what is the most effective.”

Chmielus said they want to find the best way to understand how ExOne’s additive manufacturing process can offer advantages in producing a better filter.

“We want to look at how this filtration can be predicted based on simulations and modeling,” he said. “So we’re giving (Ansys) data from our micro-structural scans, and trying to figure out how all this coordinates to create the most effective filter.”

Hartner said the group also is looking at using copper-filter technology for larger applications such as HVAC in buildings.

“The great thing about this technology is not just the design freedom but also the scalability,” he said. “We started with the concept of PPE, but that world is very oriented toward the supply chain they already have.”

Hartner said Pitt researchers will be looking into the use of 3D-printed copper filters for traditional buildings, clean rooms like a surgical theater in hospitals or air filtration aboard airplanes.

“I think people are very interested in the whole concept of not having to throw away these filters,” he said. “Reusing them and not tossing them in the landfill is a unique concept that can change both the supply chain and be better for the environment.

“There are some great payoffs if we can actually make this a reality,” he said.