Matthew Reed, vice president for academic affairs at Westmoreland County Community College, didn’t plan for the launch of the school’s new engineering program to coincide with the opening of its makerspace.

“It’s kind of a happy accident,” he said with a laugh.

The college’s board of trustees approved the two-year engineering degree program this week. It will help students pursuing a variety of engineering specialties — such as electrical, mechanical, civil and structural engineering — complete introductory courses at a lower cost before completing their degrees at a local four-year school, Reed said.

“The first two years are fairly common to most of those areas — the math, the physics, the intro to engineering,” he said.

Pitt, Point Park and PennWest universities have expressed interest in partnering with the college, accepting Westmoreland’s engineering students after they have completed the two-year program.

“They’re enthusiastic about working with us,” Reed said.

The program will be available to students starting in August — just eight months after the college opened to the public a makerspace at its Hempfield Business and Industry Center.

‘Something for any kind of maker’

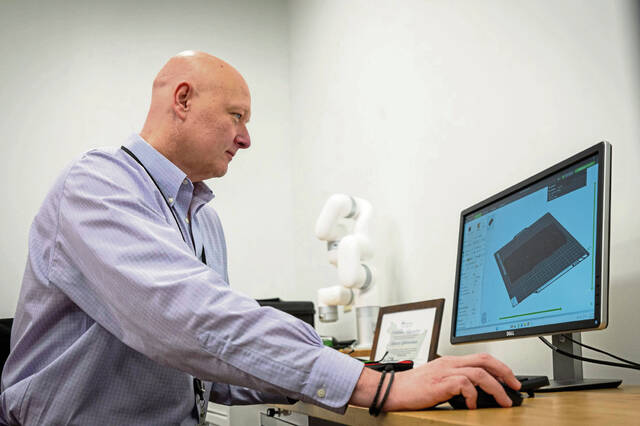

The $1.2 million space, called MADE, includes three sections — an innovation lab, design and textile studio and a woodworking and metalworking shop, said Megan Sheesley, executive director of advancement and community engagement. It includes devices such as 3D printers, laser cutters, a desktop CNC machine, vinyl printers and digital sewing machines.

“We’ve really got something for any kind of maker,” she said.

Reed believes the space will be useful for the college’s new engineering students.

“If you know any engineers, they like to tinker,” Reed said. “We can give them all the theory training, classroom training, which any schools would. But we can also turn them loose in the makerspace to experiment with stuff because that’s where they really connect theory to practice.”

Makerspace draws more than 100 members

The makerspace has gathered more than 100 members — from the student body and the community, Sheesley said.

The college is working with each of its departments to determine how the space can be integrated into students’ coursework. The dental department, for example, inquired about using the space’s 3D printers to make models of teeth, Sheesley said.

“We’ve got folks who are in here prototyping ideas that they’ve had for a long time and haven’t had the resources to pursue themselves,” she said. “We’ve got folks who are working on craft projects, people who are here just because they’re intrigued and they don’t have a specific project in mind yet, but they want to come to a space where they can learn and imagine and explore.”

A “Build Back Better” grant from the federal Economic Development Administration paid for makerspace construction and the first several months of memberships. After April, memberships will cost $49 for an individual, $89 for teams and $119 for families. A student discount is still being determined, Sheesley said.